- Alaskan Yachts

- Azimut Yachts

- Back Cove Yachts

- Beneteau Yachts

- Benetti Superyachts

- Bertram Yachts

- Boston Whaler

- Broward Yachts

- Buddy Davis Sportfish

- Burger Yachts

- Cabo Yachts

- Catamarans

- Carver Motoryachts

- Center Console

- Chris-Craft Yachts

- Cruisers Yachts

- DeFever Trawlers

- Dufour Sailboats

- Fairline Yachts

- Feadship Yachts

- Ferretti Yachts

- Formula Yachts

- Fountaine Pajot Cats

- Grady-White

- Grand Banks Trawlers

- Hargrave Yachts

- Hatteras Yachts

- Hinckley Picnic Boats

- Horizon Yachts

- Hydra-Sports

- Intrepid Boats

- Jarrett Bay Sportfish

- Jeanneau Yachts

- Kadey-Krogen Trawlers

- Lazzara Yachts

- Lekker Boats

- Luhrs Sportfish

- Marlow Yachts

- Maritimo Yachts

- Marquis Yachts

- McKinna Motoryachts

- Meridian Yachts

- Midnight Express

- MJM Yachts

- Mochi Craft

- Neptunus Motoryachts

- Nordhavn Trawlers

- Nordic Tugs

- Numarine Yachts

- Ocean Alexander Yachts

- Offshore Yachts

- Outer Reef

- Oyster Sailing Yachts

- Pacific Mariner Yachts

- Palmer Johnson Yachts

Dufour Yachts :: How the Boats Are Built (Part 1)

January 27, 2015 10:56 am

All Dufour Yachts are built in La Rochelle, France. They all combine fine hand craftsmanship with innovative high-tech construction techniques. It all starts with the hull, and this is how it’s done.

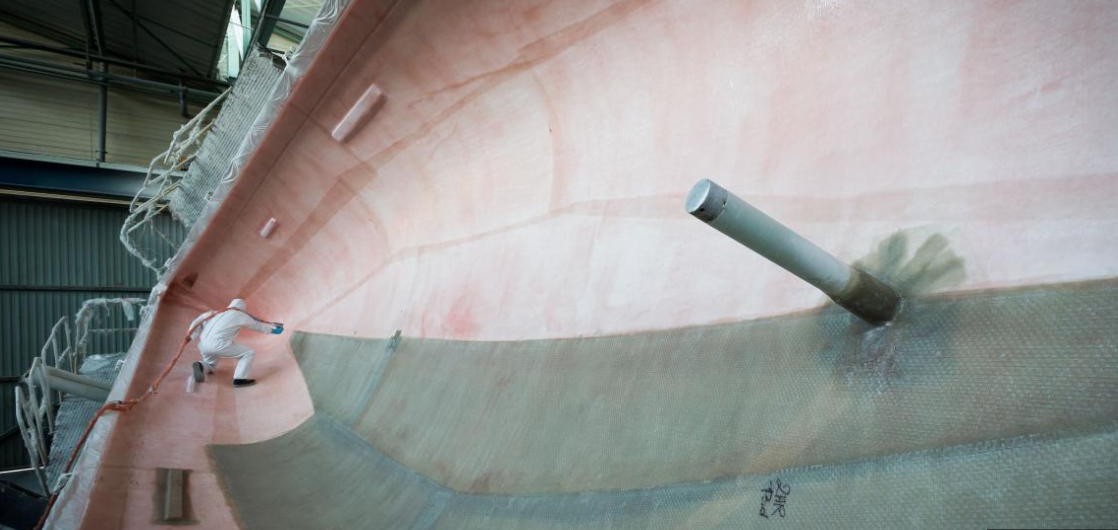

It actually all starts in a hull mold (pictured above). It starts with a flawless, highly polished 2-piece mold and then spray layers of gelcoat that form the outer layer of each hull. Each hull is then laid up with a precise, highly-engineered number of layers of fiberglass, resin, and various core materials that are all placed in each mold by hand.

Here you can see the hull is beginning to take shape. Notice the layers of fiberglass and resin that have already been applied. Also notice how the rudder area is reinforced. All molds are built on special rollers (pictured below) so they can be rotated in-place. This makes it much easier for workers to lay the various layers.

This shot shows the underside of one of the molds. And as you can see, they are extremely well-built to extremely high tolerances so every hull comes out perfect. You can also see how much they can be rotated in place. Rotating molds speed production and increase quality because they are much easier to work on than static molds.

All Dufour hulls below 50-feet are built of solid fiberglass while the 500 GL (pictured above) and the 560 GL are laid up with solid fiberglass below the waterline and PVC core above the waterline to provide strength and stiffness. This photo also shows how workers reinforce high-load areas such as chainplate connections and keel areas with increased layers of fiberglass and resin.

Another important element of hull lamination is the fact that Dufour uses 2-part molds as you can see in the photos above. This makes it easy to release the finished hull from the mold, and it also allows for an inward-facing flange that forms a strong and elegant inward-facing hull-to-deck joint.

One of the first elements that’s added to freshly laid-up hull is the structural grid. This shot also shows what the inward-facing flange looks like and some of the other early tasks that are done at this stage like cutting out the hull ports and installing a strip of PVC core material to the aft area of the hull to provide increased stiffness.

As a result of the high attention to detail paid in the early stages of construction, each hull comes out of the mold looking clean, sexy, and fast.

Dufour is never satisfied with the status quo and their high-tech facility allows Dufour to build the best because every element of the production line is constantly being upgraded. Dufour is always to looking to improve efficiency and performance.

For more information about Dufour Yachts, contact Denison Yacht Sales, the exclusive dealer for Dufour at Sales@denisonyachtsales.com | +1 954.763.3971